Trivalent Chromium Plating | Eco-Friendly & Durable Finishes

In the electroplating industry, various surface treatment are used to enhance product competitiveness by modifying properties like conductivity, texture, and color. Among these, trivalent chromium plating stands out for its popularity and eco-conscious advantages, making it a top choice across multiple industries.

Hexavalent vs. Trivalent Chromium Plating: What You Need to Know

Reliable Trivalent Chrome Plating Manufacturer And Supplier

Currently, we supply high-quality trivalent black chromium and trivalent white chromium plastic auto parts to well-known brands such as Mahindra, Infiniti, Volvo, and Volkswagen, among others.

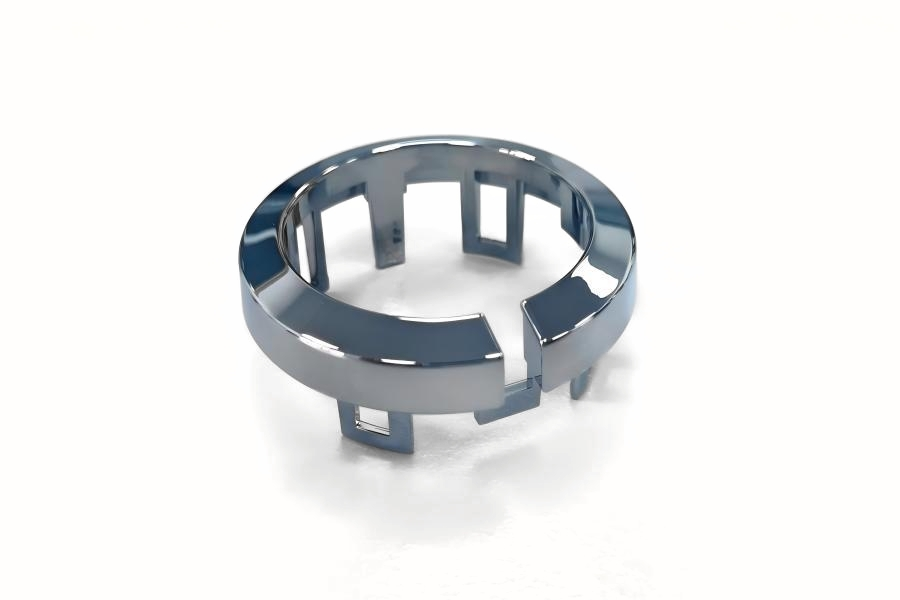

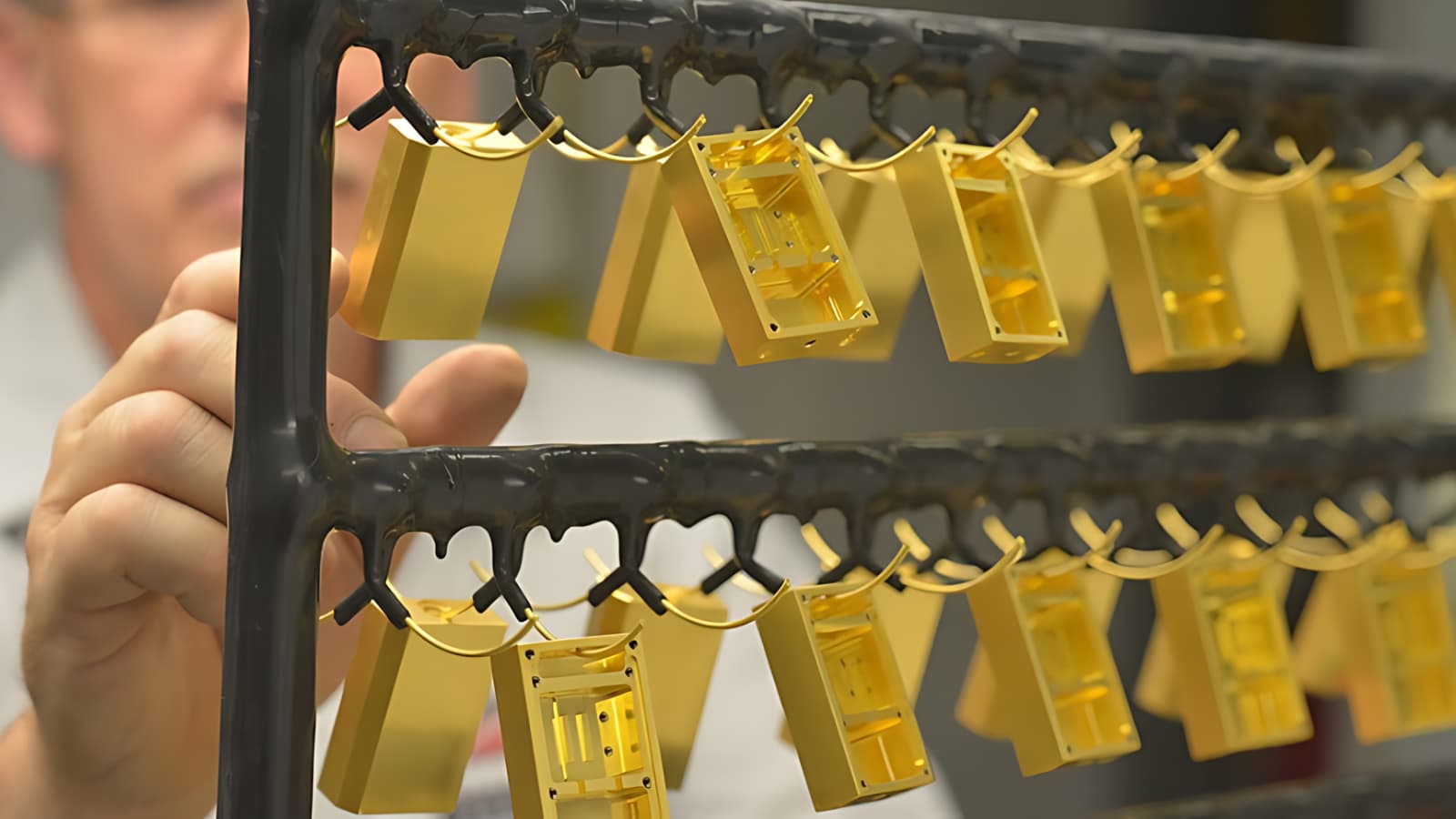

The images below showcase some of our ongoing productions, including door trims for Infiniti, door handles for Mahindra, and emblems for Volvo.

If you have any questions about trivalent chromium plating or its applications, don't hesitate to contact us. As your trusted electroplating experts, we are here to provide the best solutions for your needs!

Application Areas of Trivalent Chromium Plating for Plastic Parts

As the WHO, EU, EPA, and other organizations intensify their focus on environmental protection, trivalent chromium plating, known for its sustainability, is gaining widespread adoption.

a. Wide range of applications in industries such as automotive, sanitary, consumer goods, and electronics.

b. Ideal for plated products that use resins like ABS, ABS+PC, and other substrates.

Therefore, more and more car manufacturers are tending to use trivalent chromium plating alternative to traditional hexavalent chromium plating.

Trivalent chromium plating on automotive plastics is increasingly used. Please see the following details:

- Exterior Trim Parts: Parts like door handles, mirror housings, and grilles benefit from trivalent chromium plating, which enhances their metallic luster and corrosion resistance.

- Interior Parts: Items such as instrument panels and door trims gain a smooth, metallic finish that adds luxury and wear resistance.

- Chassis and Mechanical Components: Parts like sensors, switches, and connectors are protected with a metallic layer that improves durability and corrosion resistance.

In summary, trivalent chromium plating enhances the appearance, durability, and performance of plastic automotive parts, meeting industry demands for high-quality, functional components.

Decorative, Efficient, Sustainable: The Future of Plating

Elevate design standards with trivalent chromium plating, a sustainable alternative to hexavalent chromium that offers a versatile spectrum of finishes, from bright, clear tones to rich, deep shades.

Trivalent Chrome Colors

| TriChrome Ice | Offers a finish that match hexavalent Chrome |

| TriChrome Plus | Bright, clear, fast, CaCl₂ resistant |

| TriChrome Smoke 2 | Warm grey tone |

| TriChrome Shadow | Cool grey tone |

| TriChrome Graphite | Dark, warm finish |

Why Should We Choose the Trivalent Chromium Plating for Plastic Parts

Hexavalent chromium plating, once a standard in the industry, is increasingly phased out due to its toxic and carcinogenic properties. Trivalent chromium, on the other hand, is far less harmful to both workers and the environment. It complies with global environmental regulations, such as REACH and RoHS, making it a sustainable option for industries aiming to reduce their ecological footprint.

Choosing trivalent chromium plating for plastic parts is a smart choice that combines environmental benefits, visual appeal, and strong performance. As industries evolve, this sustainable process is becoming the standard for high-quality plating.

Looking for a trusted partner for trivalent chromium plating on plastic parts? At Cheeyuen, we offer advanced plating solutions to ensure top-quality and compliance in your products. Contact us today to explore our innovative plating technologies!

People Also Read:

Typically, trivalent chromium electroplating solutions rely upon either chloride or sulfate-based electrolytes. The process of trivalent chromium electroplating usually requires several steps between chemical treatment and electroplating process. Variations exist in production technologies.Usually,our production line must first thoroughly clean a work piece to remove debris and grease. Depending upon the composition of the part,we'll apply one or more pretreatments. For instance,we first electroplate parts with nickel prior to applying decorative chromium plating.

Trivalent plating produces at least five percent fewer rejects than hexavalent plating. You'll save money on scrap metal and can plate more parts in the trivalent bath, which will increase production. Trivalent plating also boasts: Fewer toxic fumes than hexavalent plating.

Click here for a comprehensive overview.

It is a decorative chrome plating, which can provide scratch and corrosion resistance in various color options. Trivalent chrome is considered the eco-friendly alternative to hexavalent chromium.

Next, Let’s take a closer look at this process to understand its benefits and drawbacks.Click here to view.