Why We Choose to Plate the Plastic Products?

1. Aesthetics

Aesthetic appeal is the primary reason for using chrome plating on plastic processes. Over the past few decades, plastic has often been perceived as cheap and unattractive, especially compared to metals. Manufacturers aim to avoid this perception, striving to make their products to look high-end. However, the cost of plastic is typically 5-10 times lower than that of metals, a factor that can not be overlooked if we talk about the scale of automobile industry where hundreds of millions of parts are produced all over the world. This is where plastic chrome plating comes in, offering gloss, reflective metallic finish while maintaining an impressively low price.

This metallic finish can significantly enhance the visual appeal of automotive parts like grilles, trim pieces, and wheel covers, as well as consumer products such as household appliances, electronics, and bathroom fixtures.

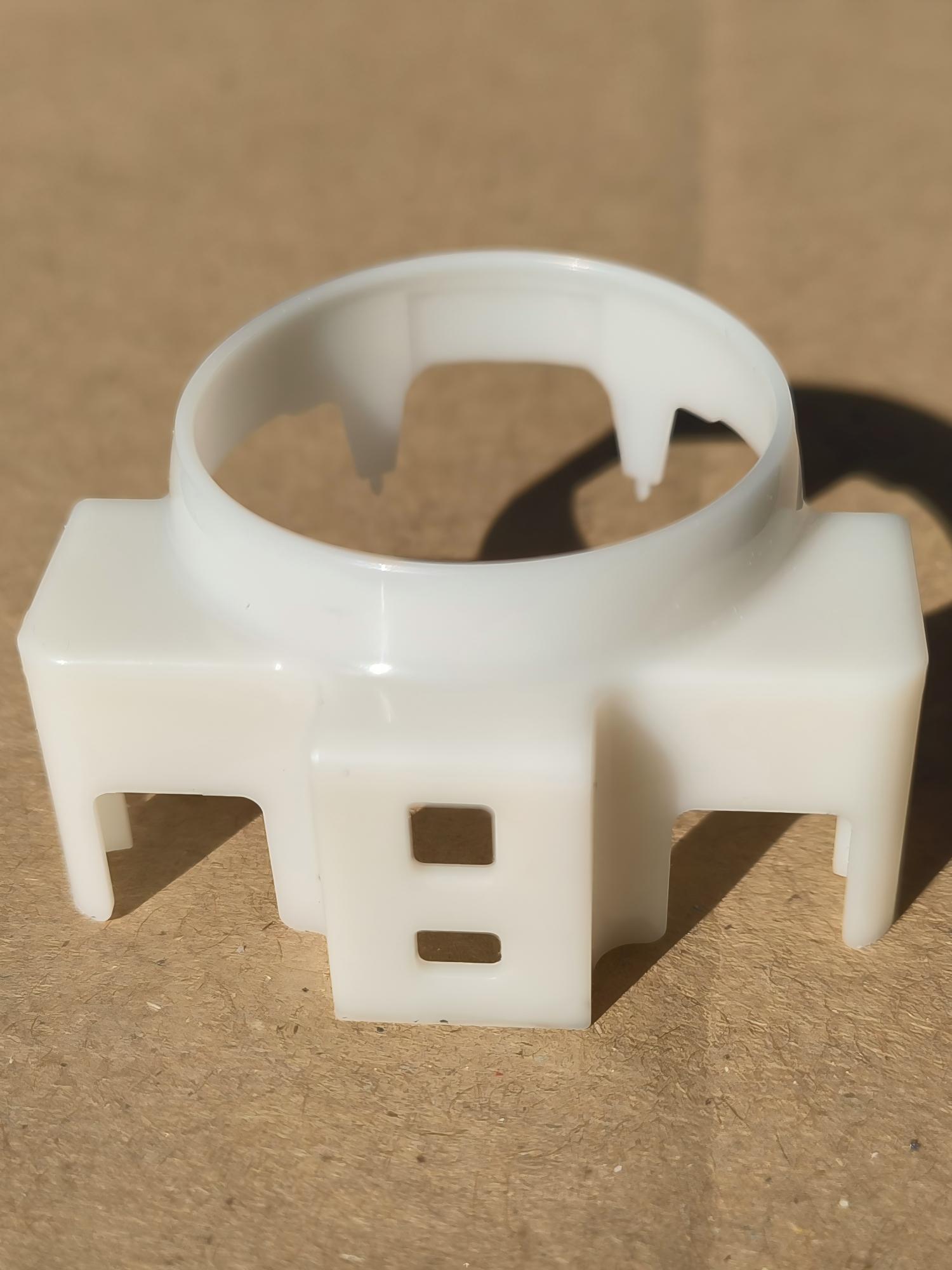

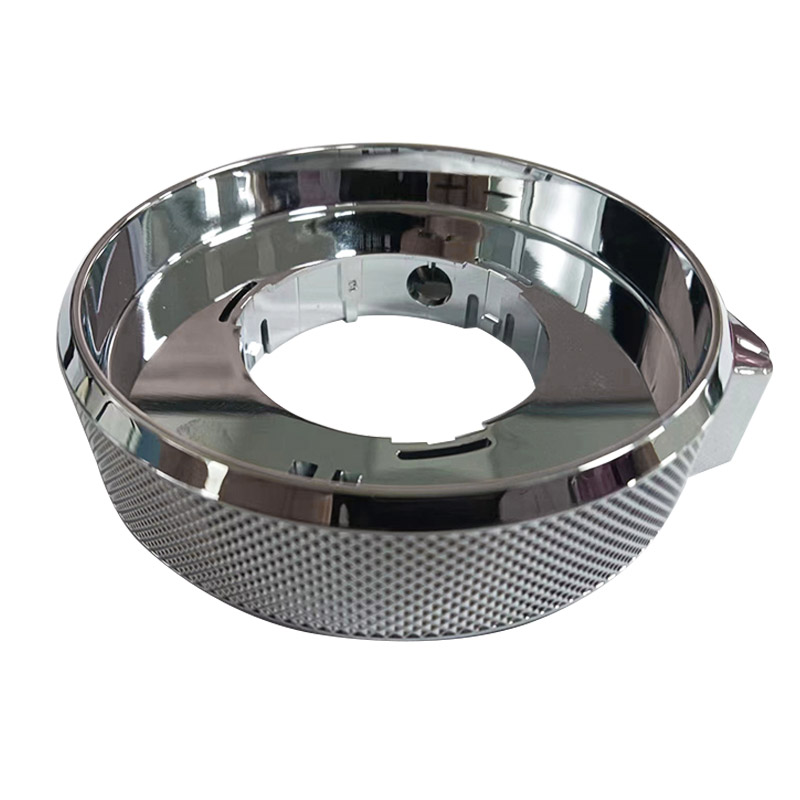

Huge Difference in Gloss between Plated plastic parts and Plastic parts

2. Superior Durability and Corrosion Resistance

We’ve all encountered the phenomenon where plastic items like buckets, watering cans, and bottles become brittle after a few years of use. With just a small amount of pressure, these items can break into pieces. This is due to plastic's tendency to degrade over time, especially when exposed to UV light, moisture, or temperature changes.

However, when plastic components are chrome-plated, the protective chrome layer significantly enhances their durability, preventing them from becoming brittle or fragile.

Corrosion Resistance: Chrome-plated plastic can last 10 to 20 years outdoors, while uncoated plastic may become brittle within a few years of exposure.

Impact Resistance: Chrome plating boosts plastic’s impact resistance by 5-10%, making it less prone to scratches and chips compared to untreated plastic, which is more likely to crack under stress.

Moisture Protection: The chrome layer forms a barrier that protects plastic from moisture, preventing it from softening and weakening in high-humidity environments like bathrooms and kitchens.

Automotive Performance: In the automotive industry, chrome-plated plastic can resist degradation by 30-50% more than uncoated plastic, even when exposed to road salts, water, and harsh chemicals.

Plastic Products That Chose Plating

3. Lightweight and Cost-Effective

Reducing weight is a critical focus in automotive design, especially with the rise of electric vehicles (EVs) and fuel-efficiency standards. Compared to metal-plated parts, plastic chrome plating offers a much lighter alternative while retaining durability and aesthetic appeal.

For consumer products, lightweight materials simplify handling and reduce shipping costs, offering economic benefits to both manufacturers and customers.

4. Increased Product Lifespan

By providing a strong, durable protective layer, plastic chrome plating extends the lifespan of both automotive and consumer products. The corrosion resistance, combined with improved durability against scratches and impacts, ensures that products can withstand the rigors of daily use, harsh weather, and mechanical stress. This translates into fewer replacements and longer-lasting products for consumers and manufacturers.

5. Broad Application Across Various Industries

Plastic chrome plating can be applied to a wide range of plastic materials, including ABS, polycarbonate, and other engineering plastics. This makes it suitable for a variety of industries, including automotive, electronics, home appliances, and bathroom accessories. Whether it's for exterior car parts, interior trim, or decorative home products, plastic chrome plating offers an effective solution for numerous applications.

People Also Ask

What material can be used for plastic chrome plating?

Common materials include ABS, PC/ABS, and other engineering plastics.

Can CheeYuen Customize Plating Products?

Yes, CheeYuen offers customizable finishes and colors to meet specific design requirements. With over 50 years of experience in plating plastic products since 1970, CheeYuen has developed extensive expertise in providing tailored finishes and solutions.

What maintenance is required for plastic chrome plating?

Every month, our PMC department will schedule a short stop for plating line allowing the bath tanks to be thoroughly rinsed and cleaned. This regular maintenance ensures the plating line remains in optimal condition and continues to perform effectively for years.

How does plastic chrome plating improve fuel efficiency in cars?

By reducing the weight of components, cars require less energy to operate, enhancing efficiency.

Post time: Dec-31-2024