1. Understanding Plastic Chrome Plating

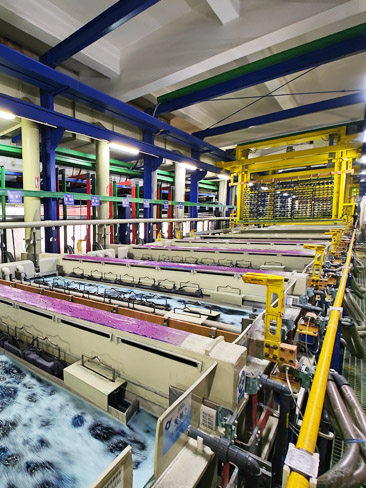

Image of Cheeyuen's Automated Plating Line

Plastic chrome plating is a process where a metallic finish is applied to plastic components, combining the lightweight benefits of plastic with the premium appearance and durability of metal. This innovative technique delivers exceptional results for a variety of industries, blending functionality with aesthetic appeal.

Key Benefits of Chrome Plating on Plastic:

- Enhanced Aesthetic Appeal: Provides a sleek, metallic finish for a high-end look.

- Improved Durability: Protects against corrosion, UV damage, and wear.

- Lightweight Advantage: Ideal for automotive and decorative applications.

CheeYuen is a renowned injection molding and electroplating company with a 54-year legacy, recognized for its outstanding products and industry expertise. With a steadfast commitment to quality and innovation, CheeYuen continues to set benchmarks in the field of plastic chrome plating.

2. Custom Plastic Chrome Plating Services: Tailored Solutions for Your Needs

Our Customization Options Include:

- Material Compatibility: Expertise in working with ABS, PC-ABS, and other composite materials.

- Finish Variations: From glossy to matte and textured surfaces, we provide finishes to match your aesthetic and functional goals.

- Advanced Coatings: Incorporating water-based and environmentally friendly coatings to meet industry standards.

With a focus on precision and customer satisfaction, we ensure that each project is completed to the highest standards, meeting both technical and visual expectations.

3. Rigorous Quality Control

Image of Cheeyuen's inspector examing chromed parts

Inspection is a vital component of Cheeyuen's comprehensive quality control system. As a crucial step in ensuring product excellence, it involves a detailed evaluation of chrome-plated parts to identify any defects or inconsistencies. From surface finish to color uniformity and structural integrity, every aspect is meticulously checked to meet industry standards and client specifications.By integrating inspection into a broader quality control framework, Cheeyuen ensures that each product not only fulfills functional requirements but also reflects the company’s unwavering dedication to precision and reliability.

As a professional plastic chroming service, we excel in:

Environmental compliance: Adhering to strict global standards, including RoHS-compliant plating and REACH-certified processes.

Reliable production: Streamlined processes ensure on-time delivery with consistent results for high-volume chrome plating projects.

Expertise: Our skilled team performs detailed inspections and testing for every product, ensuring uniformity and quality throughout the chromium plating process.

Common Challenges in Plastic Chrome Plating

Achieving consistency in the chrome plating on plastic process requires overcoming challenges such as:

Surface preparation: Ensuring the base material is clean and defect-free to avoid imperfections during the plastic plating treatment solutions phase.

Adhesion issues: Using advanced pre-treatments and adhesion promoters to secure a strong bond during the chromium plating process.

Environmental factors: Managing variables like temperature, humidity, and chemical concentrations to produce a flawless chrome finish on plastic every time.

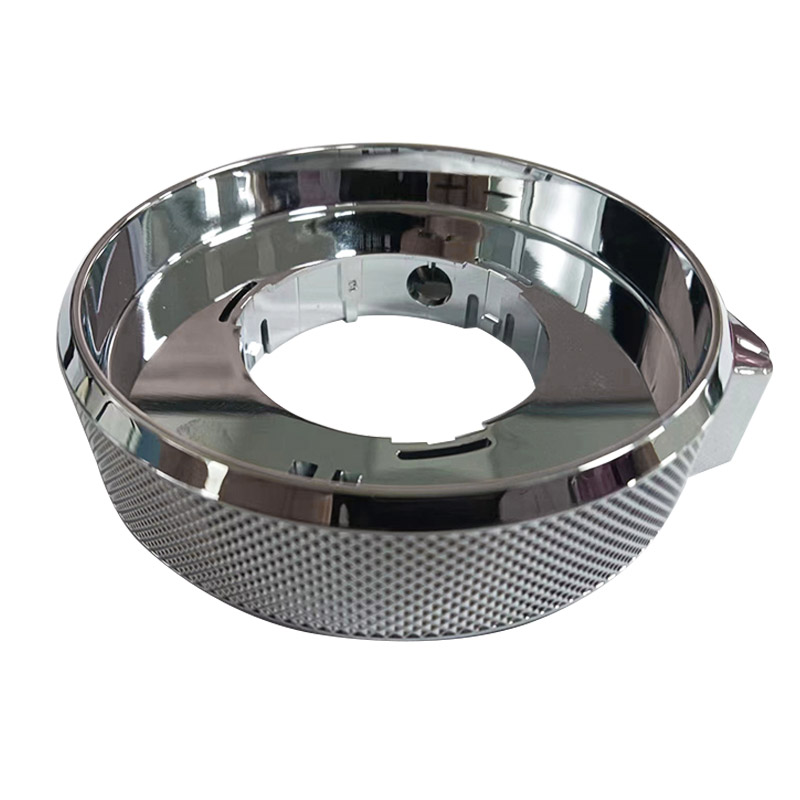

Plastic Plating Line Capability

Future Trends in Chrome Plating

As industries move toward sustainability and innovation, plastic chrome plating companies are embracing new technologies such as:

Eco-friendly chrome solutions: Adoption of water-based coatings to reduce environmental impact while maintaining premium quality.

Advanced chrome finishes: Development of fingerprint-resistant coatings and ultra-matte finishes, enhancing functionality and aesthetics.

Electric vehicle applications: Focus on lightweight and aesthetic chrome-plated EV parts, perfectly aligning with emerging automotive trends.

To ensure product quality and boost customer confidence, we have a comprehensive inspection system in place that tests and analyzes every process.

Main Customers

Credentials

The company has passed the ISO9001 quality management system and ISO14001 environmental management system certifications, as well as the ISO/IATF16949 automotive product quality management system certification.

D-U-N-S Certification

IATF 16949 for Automotive Industry

ISO9001 for Quality Management System Standard

Iso14001 for Environment Management System Standard

Awarded by Continetal Customer

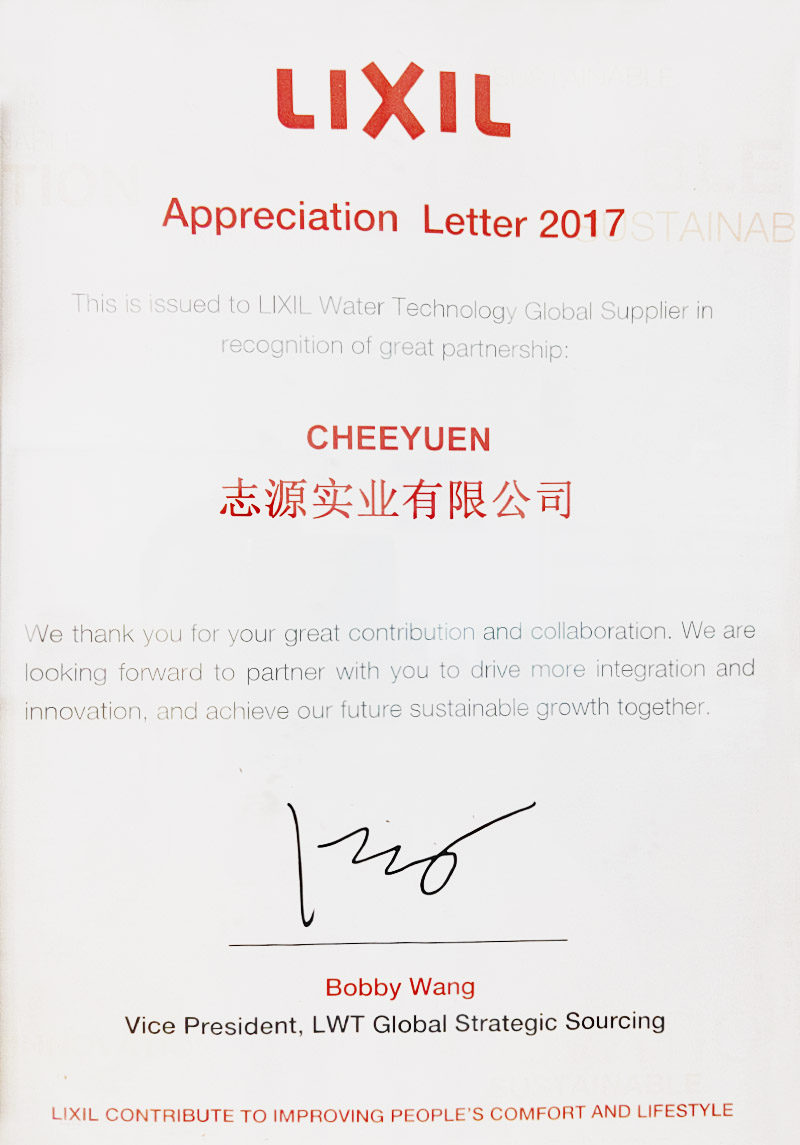

Awarded by LIXIL

Frequently Asked Questions| Plastic Chrome Plating

What is the cost structure for plastic chrome plating services?

The cost structure for plastic chrome plating can be broken down into: Tooling, Molding, Plating, other Secondary Processes such as brushing, masking, painting, assembly. then followed by packaging, transportation.

What makes the chromium plating process more environmentally friendly?

The chromium plating process has become more environmentally friendly by adopting water-based coatings, reducing heavy metal usage, and ensuring compliance with RoHS and REACH standards to minimize environmental impact.

How do plastic plating treatment solutions enhance product durability?

Plastic plating treatment solutions improve durability by creating a strong bond between the chrome coating and the plastic surface, providing resistance to corrosion, wear, and harsh environmental conditions.

Is high-quality plastic chrome plating service suitable for small batch production?

Yes, high-quality plastic chrome plating can be tailored for small batch production, ensuring each part meets the same high standards of finish, durability, and consistency.

How can plastic chrome surfaces maintain long-lasting corrosion resistance?

Through advanced surface preparation and the use of durable chrome coatings, plastic chrome surfaces are designed to provide long-lasting resistance to corrosion and environmental factors.

What is the importance of surface preparation in the plastic chrome plating process?

Surface preparation is crucial to remove impurities and ensure proper adhesion of the chrome coating, leading to a smooth, even, and long-lasting finish.

Can plastic chrome plating services meet the unique demands of different industries?

Absolutely. Plastic chrome plating services are highly customizable and can cater to various industries such as automotive, home appliances, and bathroom fixtures with specific requirements.

How do plastic chrome plating services balance delivery time with quality control?

By employing efficient production processes and thorough quality checks at every stage, plastic chrome plating services ensure that both timely delivery and high-quality results are achieved.

Post time: Dec-24-2024